We are dedicated to implement sustainable practices,

reaffirming corporate responsibility to ensure

a more long-lasting future for our society.

IN HOUSE PRODUCTION LINE

DDK proudly maintains a 98% in-house production model, epitomizing our dedication to sustainable practices.

Our practices revolves around purchasing only raw materials such as PU, steel wire, PP, and cover, enabling us to oversee and manage the entire value chain internally.

By bringing production in-house, we've orchestrated a streamlined process that minimizes waste and optimizes resource utilization. This integrated approach allows for meticulous control at every stage of production, ensuring not only high-quality outputs but also a reduced environmental footprint. Embracing this in-house production strategy embodies our unwavering commitment to sustainable and responsible manufacturing practices.

CARBON EMISSION

In pursuit of a sustainable future, DDK has taken significant strides to reduce carbon emissions.

One pivotal step involved the comprehensive adoption of solar energy in 2020, with the installation of solar panels covering our entire factory. This strategic move not only decreased our reliance on conventional energy sources but also significantly lowered our carbon footprint. In September of 2021, solar power has generated 16% of the total power usage in our manufacturing line.

Additionally, with automatic packaging, we‘ve championed eco-conscious packaging by implementing a recycle package policy, utilizing recycled materials, and completely eliminating the use of polybags.

These measures collectively underscore our dedication to minimizing environmental impact and fostering a greener, more sustainable operational framework. We are confident to reach the target of 25% CO² reduction in 2025

ENERGY OPTIMIZATION

Apart from generating green energy, DDK also optimizes and holds responsible water management.

In 2020, our commitment to environmental stewardship led us to revolutionize our wastewater disposal practices. Through the implementation of a cutting-edge bioreactor system, we not only met but exceeded emission standards, achieving an impressive Grade B rating. This marked a pivotal step in our journey toward responsible wastewater treatment, significantly reducing our environmental impact.

Furthermore, in the same year, our dedication to sustainable water practices expanded with the implementation of a rainwater recovery system. This innovative system allowed us to harness and reuse rainwater, further minimizing our reliance on traditional water sources while demonstrating our unwavering commitment to sustainable resource management.

Our approach revolves around the three pillars: BOOST, ENGAGE, and COMMUNICATE.

Our goal is to cultivate a thorough grasp of sustainability throughout our entire organization, guaranteeing that every individual, from top-level management to all employees, holds a strong and unequivocal awareness of sustainable practices.

Through targeted training workshops, we empower individuals with the skills and knowledge necessary to thrive in a sustainable ecosystem. This holistic approach underscores our dedication to creating an inclusive, informed, and supportive environment for all stakeholders involved.

ENGAGE

At the meantime, we collaborate closely with our partners, understanding their needs, and working collectively to implement sustainable solutions.

By integrating sustainable principles into our supply chain management, we ensure that both DDK and our partners have access to resources, guidance, and support to meet their sustainability targets.

We leverage our industry position to advocate for sustainable practices, offering mentorship, resources, and shared expertise. Through this collaborative effort, we drive a broader positive impact, fostering a more sustainable industry landscape that meets both our goals and the evolving needs of our supply chain partners.

COMMUNICATE

By promoting awareness and collaboration, we collectively propel positive change toward a more sustainable and resilient future. We actively share our sustainable development strategy, disseminating successful practices and impactful actions.

Through transparently showcasing our achievements, our aim is to inspire and encourage widespread adoption not only within our industry but also beyond. Our dedication to sharing knowledge contributes to a more sustainable and environmentally conscious global landscape.

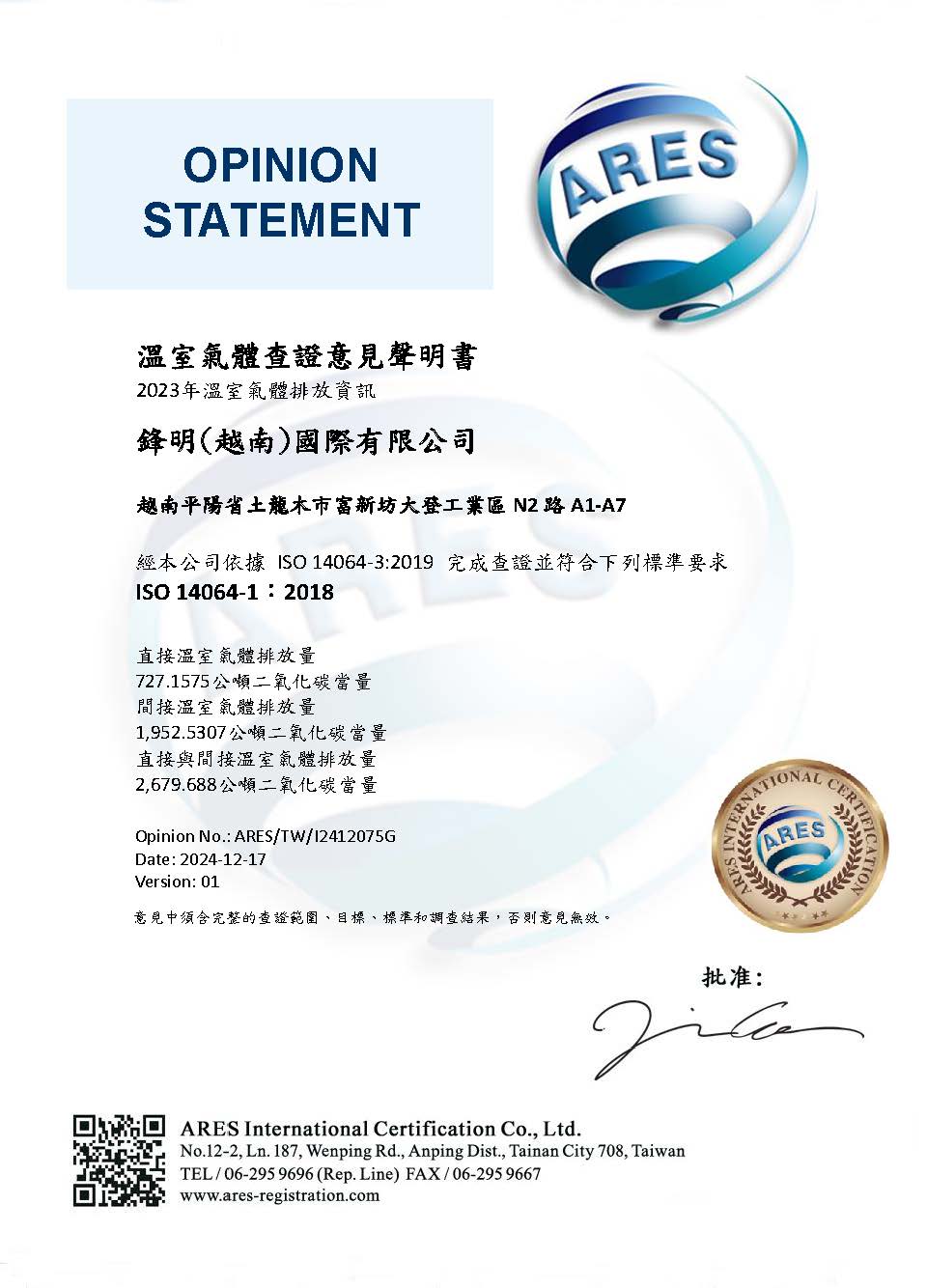

DDK Group's pride in holding multiple esteemed certifications, like SA8000, ISO 9001: 2015, ISO 14001: 2005, OHSAS 18001: 2007, ISO 45001: 2018,ISO 14064-1:2018 and REC STANDARDS, signifies the company's profound dedication to upholding excellence and sustainability across its operations.

SA8000 demonstrates its commitment to fair labor practices and social accountability.

ISO 9001 showcases the company's emphasis on quality management systems, ensuring consistent product or service delivery.

ISO 14001 highlights DDK's focus on environmental management, striving for sustainable practices.

OHSAS 18001 and ISO 45001 underscore its priority on occupational health and safety, safeguarding its workforce.

ISO 14064-1 refers to rigorous greenhouse gas verification, ensuring precision and reliability in emissions reporting, enhancing corporate accountability.

REC STANDARDS reflect the company's adherence to renewable energy practices.

These certifications serve as guiding principles, driving DDK's ongoing pursuit of superior social responsibility, stringent quality control, eco-friendly initiatives, and a safe workplace environment.